10 Operational Excellence Strategies That Actually Work

Ditch the jargon. Discover 10 practical operational excellence strategies you can implement today to unify your teams and drive real results.

Dan Robin

We’ve all seen it. The binders of 'best practices' gathering dust. The grand 'transformation' projects that fizzle out after a quarter. The problem isn't the ambition; it's the approach. We chase buzzwords and complex frameworks, forgetting that operational excellence isn't a destination you arrive at with a complicated map. It's a daily rhythm. A habit.

It's about making small, smart improvements consistently, especially for the people on the front lines who do the actual work. For years, we’ve been obsessed with finding a better way to run our businesses—not just more efficiently, but more calmly and humanely. This isn't a theoretical exercise. It's a collection of what we've seen work, time and again, for companies that get it right.

In this article, we’re cutting through the noise. We'll break down ten practical operational excellence strategies you can actually use, whether you’re running a hospital, a chain of cafes, or a busy warehouse. We’ll cover everything from Lean principles to the often-overlooked power of genuine employee engagement.

This is a no-nonsense guide. For each strategy, we’ll give you a clear path to get started, pitfalls to avoid, and real examples of how they look in action. Let's get to it.

1. Lean Operations and Continuous Improvement

Lean isn't just a process; it's a fundamental shift in how you think. At its core, Lean is about creating more value for customers with fewer resources. It’s a relentless hunt for “waste”—anything from wasted time and materials to unnecessary steps in a workflow. Pioneered by Toyota, this approach gives the people closest to the work, your front-line teams, the power to continuously spot and solve problems.

This isn’t about cutting corners. It’s about being smarter. When a hospital uses Lean to reconfigure its emergency room layout, patient wait times drop. When a retail chain analyzes its inventory process, it reduces overstock. These aren’t top-down mandates; they are improvements driven by the people who live the processes every day. And that’s why it works.

How to Start with Lean

Start Small: Don't try to overhaul everything at once. Pick one high-impact area—a single store's stockroom process or one shift's patient intake procedure—to test your approach.

Listen to Your Team: They know where the bottlenecks are. Create a simple channel where employees can easily submit ideas, photos, or short videos of what’s not working. No complex forms.

Show the Progress: Make the impact visible. Track key metrics like reduced task completion time or decreased material waste. Share these wins to build momentum.

Celebrate Small Wins: When a team's suggestion shaves five minutes off a daily task, celebrate it. This reinforces a culture of improvement and gets more people involved.

Adopting a Lean mindset is a marathon, not a sprint. For a deeper dive, explore these tips on how to improve operational efficiency and get your team started.

2. Six Sigma and Data-Driven Decisions

If Lean is about speed and waste, Six Sigma is its data-obsessed cousin, dedicated to near-perfect quality. It’s a rigorous, statistical method for eliminating defects and variation in any process. The goal is ambitious: reduce errors to just 3.4 defects per million opportunities. This isn’t about gut feelings; it’s about making decisions based on cold, hard data.

This disciplined approach turns management from an art into a science. When General Electric adopted Six Sigma under Jack Welch, it reportedly saved the company billions by systematically improving processes. In a hospital, it can mean a dramatic reduction in medication errors. It works because it provides a clear, mathematical path to improvement.

How to Start with Six Sigma

Define a Specific Problem: Start with something you can measure. Instead of a vague goal like "improve customer satisfaction," focus on "reduce call center wait times by 20% in Q3." A clear target is everything.

Measure Your Starting Point: You can't improve what you don't measure. Track key metrics, like task completion times or error rates reported by front-line staff. This data is your baseline.

Find the Root Cause: Dive into the numbers to understand why defects are happening. Look for patterns, like which shifts or locations have the highest error rates.

Implement and Control: Once you find a fix, roll it out and keep monitoring the data. Document the new standard procedure where everyone can find it, and use a task system to track the improvement from start to finish.

3. Total Quality Management (TQM)

Total Quality Management (TQM) is one of those ideas that fundamentally changes a company’s DNA. It’s a philosophy where every single person, from the CEO to the front-line associate, is responsible for maintaining high standards. TQM is built on the idea that success comes from an organization-wide commitment to continuous improvement, with a laser focus on the customer.

This isn’t about a quality control department checking work at the end of the line. It's about building quality into every step. Think of the Mayo Clinic, where patient care isn't just the doctor's job; it's the shared responsibility of the scheduling staff, the lab techs, and the cleaning crew. It’s a culture where every employee is expected to spot and fix issues before they ever reach the customer.

How to Start with TQM

Define Your Quality Standards: You can't improve what you haven't defined. Document your quality benchmarks and procedures clearly. Make these standards instantly accessible to every team member on their phone.

Create Quality Circles: Let teams own their processes. Set up dedicated channels where specific teams or shifts can discuss quality challenges and brainstorm solutions without cluttering up main communications.

Track Improvement Projects: Ideas are great, but execution is what matters. When a team identifies an area for improvement, assign ownership, set deadlines, and track the project from idea to reality.

Recognize Quality Champions: A culture of quality thrives on recognition. Let team members publicly celebrate colleagues who go above and beyond to uphold standards. This is far more powerful than any top-down memo.

4. Business Process Management (BPM) and Automation

Let’s be honest. Many businesses run on a collection of informal, "this is how we've always done it" workflows. Business Process Management (BPM) replaces that chaos with clarity. It’s about mapping out how work actually gets done, finding the weak spots, and then optimizing those processes to be more consistent and efficient. It creates a predictable foundation for everything you do.

When you add automation, BPM becomes truly transformative. Think about all the repetitive, manual tasks that eat up your team's day: filling out forms, sending reminder emails, getting approvals. Automation handles that work, freeing your people to focus on things that matter. For a logistics company, this could mean automating route planning. The goal isn't to replace people but to unburden them from monotonous work.

How to Start with BPM and Automation

Map Repetitive Processes: Start with high-frequency, low-complexity tasks like new hire onboarding or weekly supply orders. Document every step to see where the friction is.

Standardize Workflows: Use a central tool to build standardized task lists and workflows that trigger automatically. For instance, when a new employee is added, their onboarding checklist can be instantly assigned.

Automate Information Flow: Connect your systems to kill manual data entry. Integrate your employee app with your HR or payroll software so information is always in sync, reducing errors and saving time. -- Monitor and Refine: Use analytics to see how your new processes are performing. Check task completion rates and cycle times to spot new bottlenecks and continuously refine your workflows.

5. Real-Time Analytics and Performance Dashboards

You can’t fix what you can’t see. This is the heart of using real-time analytics. It’s not about pulling dusty reports at the end of the month; it’s about having a live pulse on your business. With performance dashboards, leaders get immediate visibility into key metrics, allowing them to spot trends, address issues, and make smart adjustments on the fly.

This approach moves decisions from guesswork to data-driven certainty. A hospital can use a dashboard to monitor patient flow and bed availability, preventing bottlenecks before they happen. Amazon’s logistics network relies on real-time data to track inventory with incredible precision. The goal is to see what’s happening right now, not what happened last quarter.

How to Start with Real-Time Analytics

Define Your Critical Metrics: Don't track everything. Focus on the few KPIs that truly drive your business. A retail manager might focus on sales per hour, while a logistics supervisor watches on-time delivery rates.

Make Data Accessible: Your data is useless if it's locked away. Use a tool that creates a central dashboard accessible to leaders at all levels, even on their phones.

Set Up Smart Alerts: Configure your dashboard to send notifications when key metrics cross a certain threshold—a sudden dip in customer satisfaction or an increase in incomplete pre-shift checklists. Solve problems before they become crises.

Foster a Data-Informed Culture: Use your analytics to tell a story. Share key insights and performance trends through a company news feed to help teams understand the "why" behind their work.

6. Employee Engagement and Empowerment

We often focus on processes and technology, but the most powerful asset you have is your people. Real, sustainable improvement is impossible without engaged employees. It’s about creating an environment where the people closest to the work feel trusted, heard, and equipped to make a difference. It’s a shift from a top-down model to a culture of shared ownership.

This isn’t about just making people happy; it’s about unlocking their potential. When a Southwest Airlines crew member feels empowered to make a customer’s day, it creates legendary service. When a Trader Joe’s team member has the autonomy to manage their section, the store runs better. True empowerment means giving your teams the safety, tools, and authority to spot problems and drive improvements on their own.

How to Start with Empowerment

Create Simple Feedback Channels: Don't let good ideas get lost in emails or busy shifts. Create dedicated channels where front-line employees can easily submit suggestions, report issues, and share insights.

Promote Peer-to-Peer Recognition: Build a culture of appreciation. Let team members publicly celebrate colleagues who go above and beyond, reinforcing the right behaviors.

Communicate Transparently: Keep everyone in the loop, regardless of their role or location. Use a central news feed to share company updates and wins, ensuring your distributed workforce feels like one team.

Close the Loop: The fastest way to kill engagement is to ignore suggestions. Use task management to assign, track, and report back on employee ideas, showing your team that their voice truly matters.

A crucial part of this is to foster a positive workplace culture. To learn more, explore our definitive guide to workplace engagement.

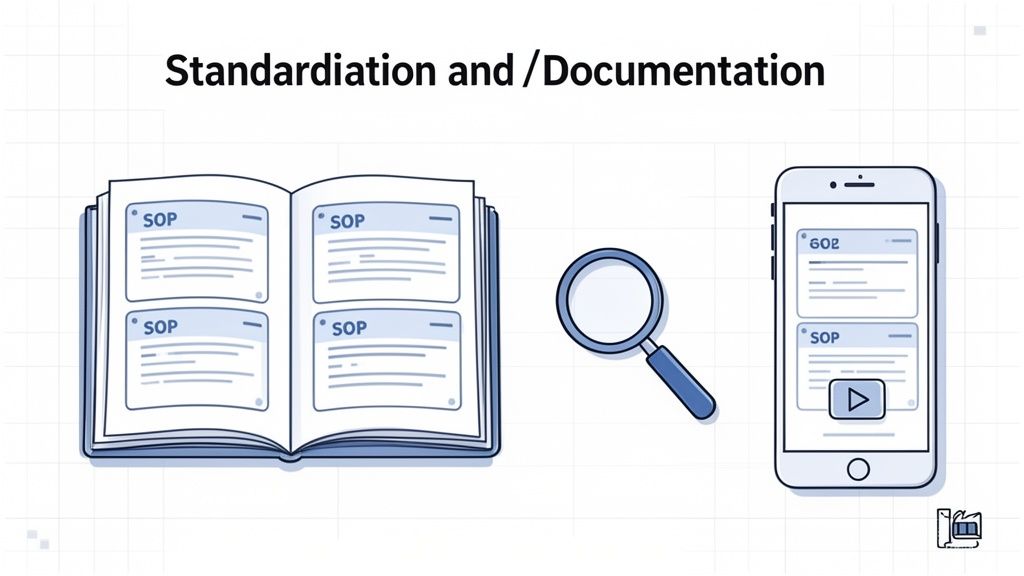

7. Standardization and Documentation of Best Practices

One of the simplest, yet most powerful, strategies is creating a single source of truth for how work gets done. Standardization isn't about stifling creativity; it’s about eliminating guesswork and ensuring every customer gets the same high-quality experience, every time. It means documenting the best, safest, and most efficient way to do any task and making that knowledge easy for everyone to find. From a Starbucks barista making a latte to a hospital team following a clinical checklist, documented practices are the bedrock of consistency.

When this knowledge lives only in the heads of a few seasoned employees, your business is fragile. Documentation democratizes expertise, making it possible to scale, onboard new hires faster, and maintain quality across all locations. It’s the difference between an operation that depends on individual heroics and one that runs on a reliable system. This is also critical for safety; for industries with risks, clear procedures are non-negotiable. For instance, teams handling high-voltage equipment must Master NFPA 70E Electrical Safety Guidance to prevent accidents.

How to Start with Standardization

Create a Central Knowledge Base: Don't let SOPs get lost in binders or scattered drives. Build a single, searchable library for all procedures and guides that employees can access from any device.

Use More Than Words: A picture or a short video is often better than a long paragraph. Supplement written instructions with quick video demos of complex tasks or photos of the correct setup.

Link Documentation to Daily Work: Connect theory to practice. Within a task checklist, you can directly link to the relevant SOP, so employees have instructions at the exact moment they need them.

Schedule Regular Reviews: Best practices evolve. Set automated reminders to review and update documentation quarterly or annually to ensure it stays relevant.

Building a comprehensive knowledge base is a crucial step. To get started, you can explore this guide on how to build a knowledge base for practical tips.

8. Supply Chain and Resource Optimization

An organization is only as strong as its weakest link, and often, that link is the supply chain. This strategy goes beyond just managing inventory; it's about the seamless flow of materials, information, and even your people's time. At its heart, it’s about getting the right resources to the right place at the right time, with minimal waste.

This isn’t just for giants like Amazon. It applies just as much to a restaurant group ensuring each location has fresh ingredients for the dinner rush or a healthcare system deploying nurses based on patient load. When a retailer like Zara can get a new design from concept to store shelf in weeks, it’s not magic; it’s a finely tuned supply chain. The goal is to eliminate friction and build a system that can respond quickly to change.

How to Start Optimizing Resources

Plan Collaboratively: Don’t let forecasting happen in a silo. Create a dedicated space where planners, store managers, and procurement teams can share insights and adjust forecasts based on what’s happening on the ground.

Optimize Your People: Your people are your most valuable resource. Use a scheduling system to align shift coverage with peak demand, ensuring you’re never overstaffed during lulls or understaffed during a rush.

Streamline Resource Allocation: Whether it's allocating equipment across hospital wards or deploying delivery vehicles, use a task system to coordinate. Assign, track, and confirm resource movements for clear visibility.

Monitor and Adjust in Real-Time: Bottlenecks can appear anywhere. Use analytics to monitor resource use. When you spot a delay, you can quickly communicate with the right teams to diagnose and resolve the issue.

9. Leadership Development and Succession Planning

Operational excellence isn't just about flawless processes; it's about the people who lead them. A strategy built on strong leadership ensures that high standards are maintained and the culture of improvement endures. This means intentionally identifying and nurturing future leaders at every level, not just hoping they emerge. It's about creating a clear path for growth so that when a key manager moves on, a capable successor is ready to step in.

This approach transforms leadership from a title into a widespread capability. When a logistics company trains its shift supervisors on conflict resolution and team motivation, it sees a direct impact on retention and uptime. The goal is to make leadership a renewable resource, building a resilient talent pipeline that ensures your standards are passed on and improved over time.

How to Start Developing Leaders

Identify High-Potential Talent: Your next great leaders are likely already on your team. Look for consistent top performers and those who actively help others across different locations and shifts.

Create Mentorship Connections: Formalize the transfer of knowledge. Use a dedicated channel to connect emerging leaders with seasoned mentors, creating a structured environment for guidance and growth.

Make Learning Accessible: Don't limit development to off-site workshops. Share leadership articles, training videos, and best practices through your knowledge library and news feed. Make learning a continuous part of the daily workflow.

Track and Discuss Progress: Use 1-on-1s to have honest conversations about career growth. Track completion of development tasks to ensure accountability and celebrate milestones.

10. Customer-Centric Operations

True operational excellence isn't just about internal efficiency; it's about how that efficiency translates into an unforgettable customer experience. A customer-centric approach realigns every process and every decision around a single goal: delivering exceptional value. It’s a mindset, not just a department, perfected by brands like Ritz-Carlton and Nordstrom, where great service isn't a script but an ingrained part of the culture.

This means deeply understanding customer needs and empowering your front-line teams to meet them. When a hotel associate is given the autonomy to instantly resolve a guest's issue without manager approval, that’s customer-centricity. When a retail team redesigns its checkout process based on direct shopper feedback, that’s how you build loyalty.

How to Build a Customer-Centric Culture

Share Customer Wins and Feedback: Your front-line teams are your brand ambassadors. Use a company news feed to instantly share positive customer reviews and success stories. This connects their daily work directly to customer happiness.

Standardize Service Excellence: Don't leave great service to chance. Document your customer service standards and best practices in a shared knowledge library. This gives every employee a single source of truth for delivering a consistent experience.

Empower Fast Problem-Solving: When a customer has an issue, speed matters. Equip your teams with direct communication channels to quickly connect with colleagues or managers to find solutions on the spot.

Celebrate Your Service Champions: Use peer-to-peer recognition to highlight employees who go above and beyond for customers. A public "shout-out" not only rewards the individual but also shows the entire company what excellence looks like.

Operational Excellence: 10-Strategy Comparison

Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Lean Operations and Continuous Improvement | Moderate→High — cultural change, pilot cycles | Low–Moderate — training, time for Kaizen | Reduced waste, faster processes, higher quality 📊 ⭐⭐⭐⭐ | Multi-shift frontlines, manufacturing, retail ops | Sustained efficiency gains; frontline-driven improvements |

Six Sigma and Data-Driven Decision Making | High — statistical methods, DMAIC rigor | High — data infrastructure, certified training | Dramatic defect reduction, consistent quality 📊 ⭐⭐⭐⭐⭐ | Processes with measurable defects (manufacturing, finance, healthcare) | Objective metrics and root-cause control |

Total Quality Management (TQM) | High — org-wide culture and process alignment | Moderate–High — training, long-term commitment | Strong quality culture, customer loyalty over time 📊 ⭐⭐⭐⭐ | Enterprise-wide quality initiatives, service and healthcare | Holistic engagement; supplier and customer integration |

BPM and Automation | High — process mapping and system integration | High — automation tools, maintenance, change mgmt | Eliminate manual work, increase consistency and scale ⚡ 📊 ⭐⭐⭐⭐ | Repetitive workflows: onboarding, approvals, scheduling | Automation-driven reliability; fewer handoffs and errors |

Real-Time Analytics and Performance Dashboards | Moderate–High — data pipelines and visualization | High — analytics platforms, data governance | Faster decisions, early issue detection, actionable KPIs 📊 ⚡ ⭐⭐⭐⭐ | Operations needing live KPIs (logistics, retail, hospitals) | Immediate visibility and alerting for leaders |

Employee Engagement and Empowerment Programs | Moderate — program design and leadership buy-in | Moderate — time, recognition programs, facilitation | Higher retention, productivity, frontline innovation 📊 ⭐⭐⭐⭐ | Frontline-heavy service organizations (retail, hospitality) | Stronger culture; improved discretionary effort |

Standardization and Documentation of Best Practices | Low–Moderate — authoring and governance | Low–Moderate — content creation and updates | Consistency, faster onboarding, fewer errors 📊 ⭐⭐⭐ | Multi-location operations, training-intensive roles | Scalable SOPs; reduced reliance on individuals |

Supply Chain and Resource Optimization | High — forecasting, integrations, coordination | High — systems, supplier collaboration | Lower inventory costs, improved delivery reliability 📊 ⭐⭐⭐⭐ | Retail, logistics, inventory-centric businesses | Cost savings; improved responsiveness and resilience |

Leadership Development and Succession Planning | Moderate — identification and program rollout | Moderate–High — coaching, training resources | Leadership continuity, better decision-making 📊 ⭐⭐⭐ | Growing organizations with distributed teams | Stronger leadership bench and internal mobility |

Customer-Centric Operations and Service Excellence | Moderate–High — culture, training, SLAs | Moderate — training, empowerment tools, feedback systems | Improved loyalty, revenue, brand reputation 📊 ⭐⭐⭐⭐ | Retail, hospitality, healthcare, customer-facing services | Differentiation through empowered frontline service |

It's Not a Project, It's a Practice.

We’ve just walked through ten powerful operational excellence strategies. But here’s the thing we have to be honest about: None of them are a magic wand. You can’t just "install" Lean or "turn on" TQM and expect everything to change overnight.

The real common thread isn’t the specific framework. It's the underlying principle of connecting your people to the work, to the company's goals, and most importantly, to each other. Excellence is the sum of a thousand small, informed decisions made every day by the people closest to the problems. Your job as a leader isn’t to dictate every move. It’s to give your teams the clarity, context, and tools they need to make great decisions on their own.

The Real Goal: A Calm, Connected Workplace

Think about it. When a process is documented clearly, an employee doesn't have to guess. When performance metrics are transparent on a dashboard, a supervisor knows exactly where a bottleneck is forming. When feedback is easy to give, a nurse can flag a recurring issue, leading to a system-wide improvement.

These aren't isolated events. They are the daily heartbeats of a well-run business. The secret is creating a calm, connected environment where information flows freely and feedback is treated as a gift. This is where modern tools become so critical. They can act as the central nervous system for your entire operation. But a tool is only as good as the philosophy behind it.

Your First Step

So, where do you start? Don't try to boil the ocean. Looking at all ten of these strategies at once can feel overwhelming. Resist the urge to launch a massive, company-wide "excellence initiative." That’s a recipe for burnout.

Instead, pick one thing.

Find one process that’s obviously broken.

Identify one team that feels disconnected.

Choose one metric that’s important but no one can track.

Start there. Your only goal is to make that one small thing a little bit better. Document the process. Set up a dedicated communication channel. Build a simple dashboard. Then, gather feedback, measure the change, and share what you learned.

Then do it again tomorrow.

This is what continuous improvement actually looks like. It’s not a grand transformation. It's a quiet, relentless practice of paying attention and making small, steady gains. Over time, these tiny wins compound into a powerful cultural shift, creating an organization that isn’t just efficient, but resilient, adaptive, and a genuinely better place to work. That’s the real prize.

Tired of juggling spreadsheets, chat apps, and clunky intranet portals to run your operations? Pebb brings all your communication, tasks, schedules, and training into one simple, unified app for your frontline teams. See how you can put these operational excellence strategies into practice by visiting Pebb today.